Carbon black can be used for many different applications. It is employed as a reinforcing agent in the production of tyres,imparting abrasion and tear resistance as well as important wet-grip properties.

In addition, carbon black is used to produce wiper ribbons,floor mats,engine mounts, and hoses for all types of vehicles.

It is also an essential element in paint, printing ink, batteries, electric conductors, and a broad range of rubber products.

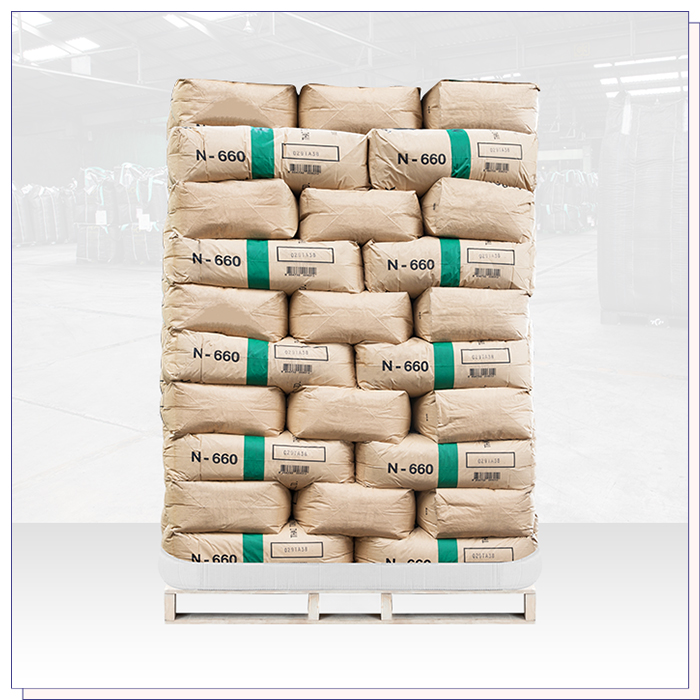

Packaging of TCP Carbon Black is

| Paper Bag | 25 Kgs/bag |

| Jumbo Bag | 500 Kgs/bag |

| Jumbo Bag | 1000 Kgs/bag |